For Custom Metal Parts

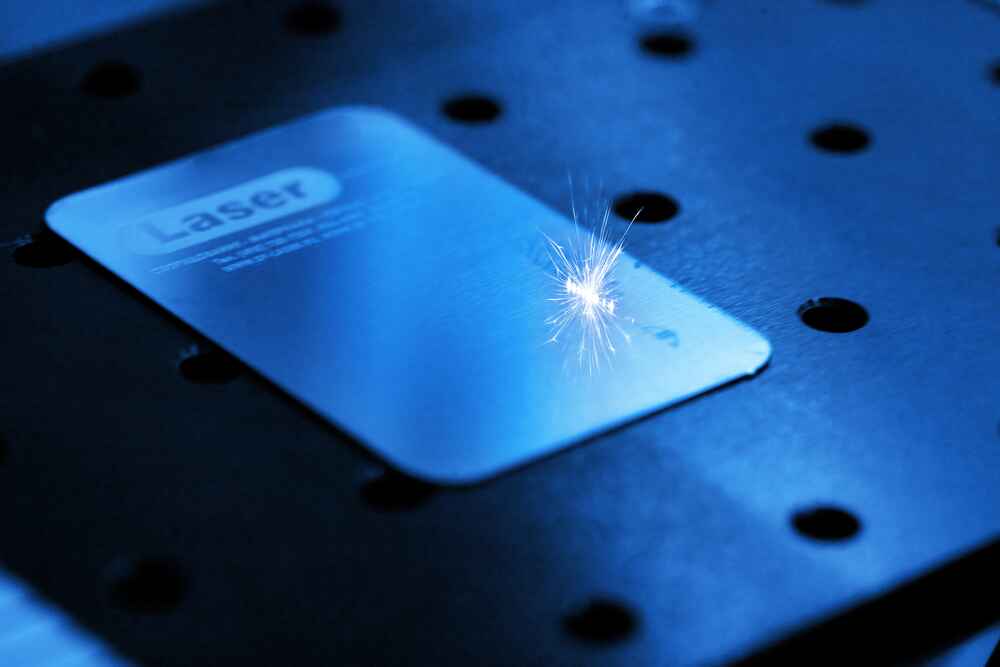

Surface Finishing

Our versatile capabilities enable us to elevate the surface quality of your components, enhancing their durability, corrosion resistance, and visual appeal. Entrust your surface finishing requirements to our industry-leading expertise and experience a new standard of excellence.

How It Works

We Are a True Partner

Your success is our priority. As a leading contract manufacturer, we prioritize manufacturing excellence so that you can prioritize what matters most.

Enabling Innovation and Creativity

Keep iterating on your innovative products. We’re here to provide assistance every step of the way.

Our Core Values

Advantages

18+ Years of Industry Experiences

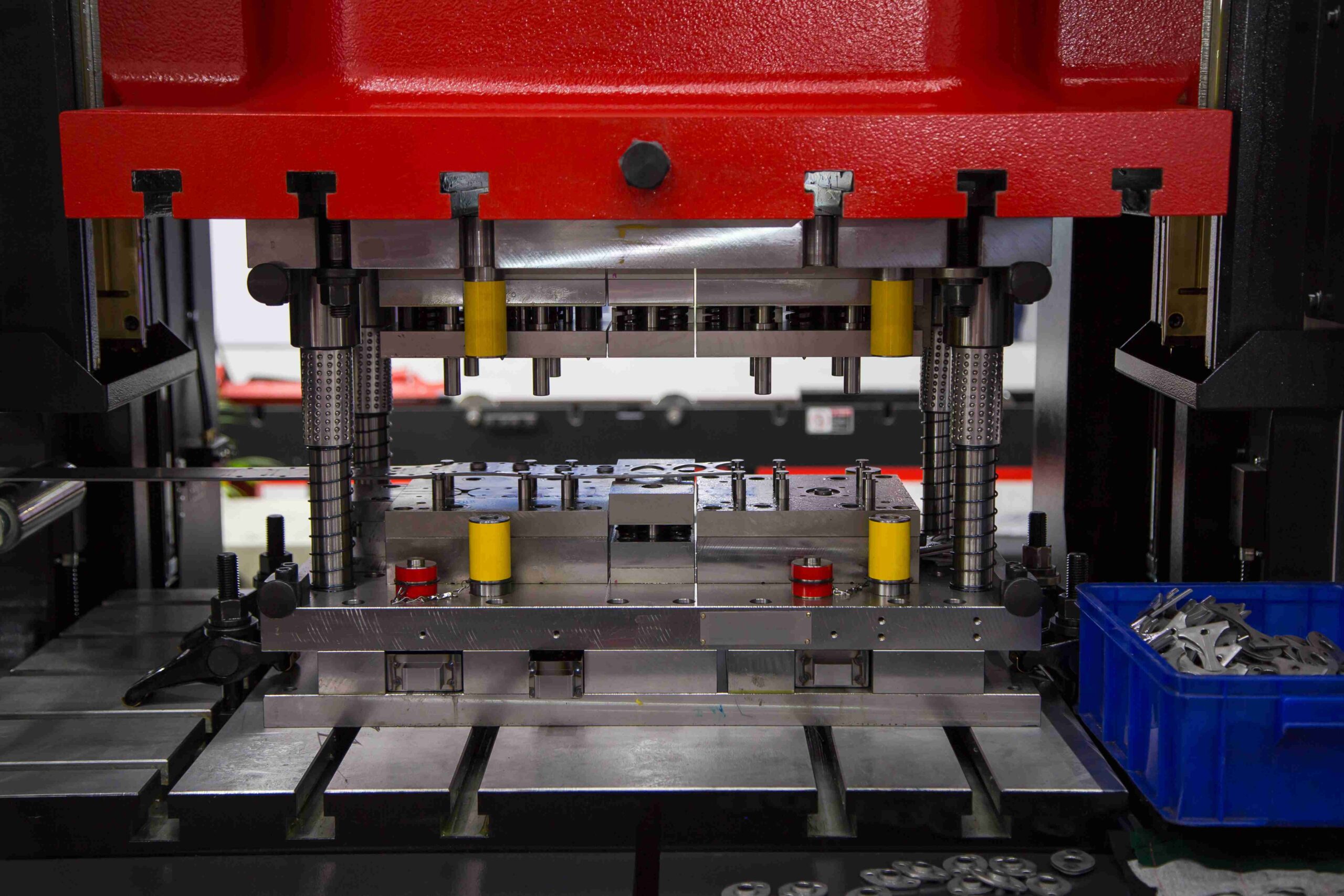

5 Advanced Manufacturing Facilities

200+ Skilled Engineers and Technicians

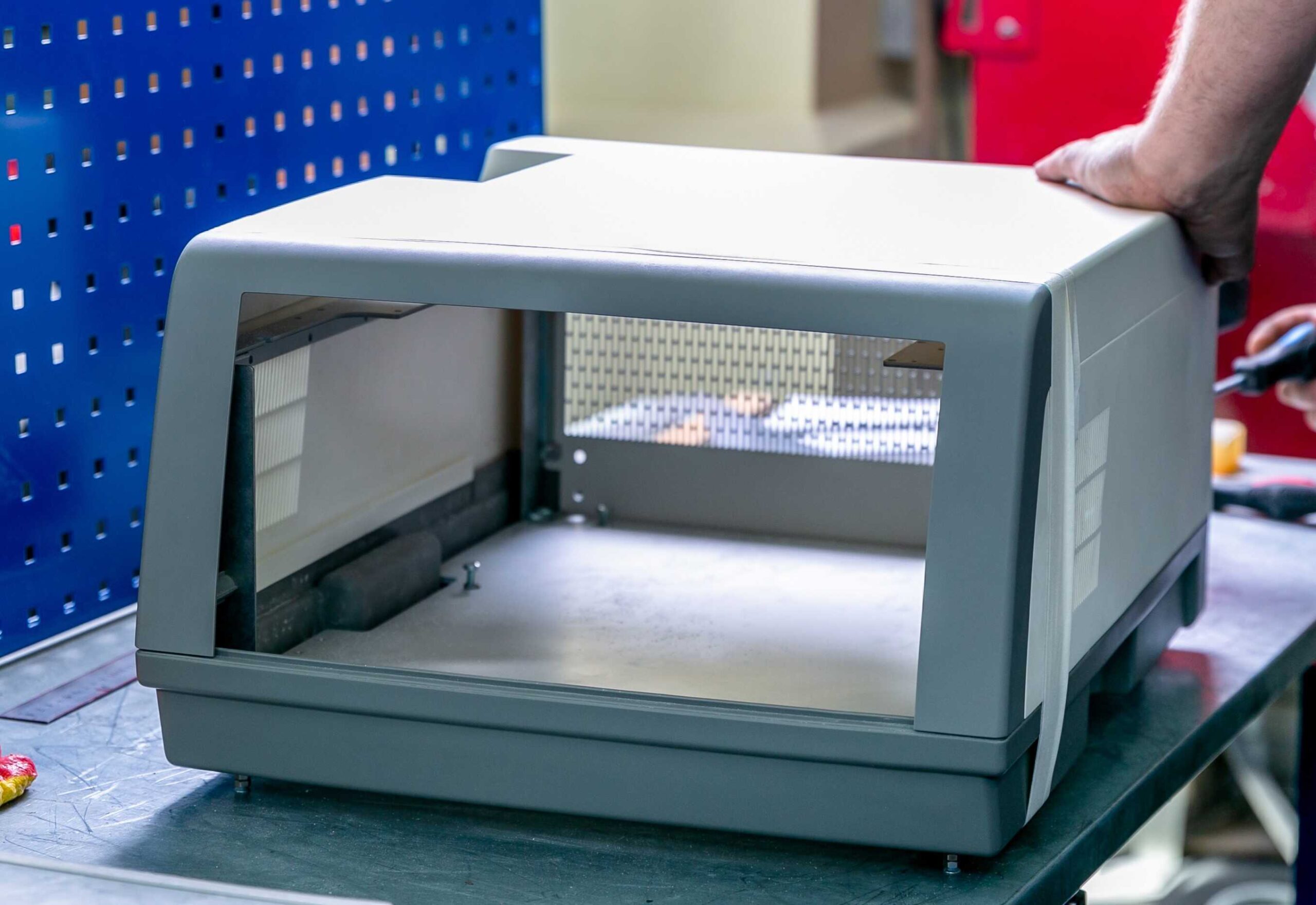

One-stop Custom Manufacturing Solutions

Trusted by Global Brands

hundreds of happy clients from over 50 countries

“The team at Sino Prototype is fantastic. They helped us with the production of our designs. Those parts look great as we’ve imagined and designed. Without hesitation, I highly recommend their custom manufacturing services.”

Supply Chain Manager

Let’s Kickstart Your Custom Manufacturing

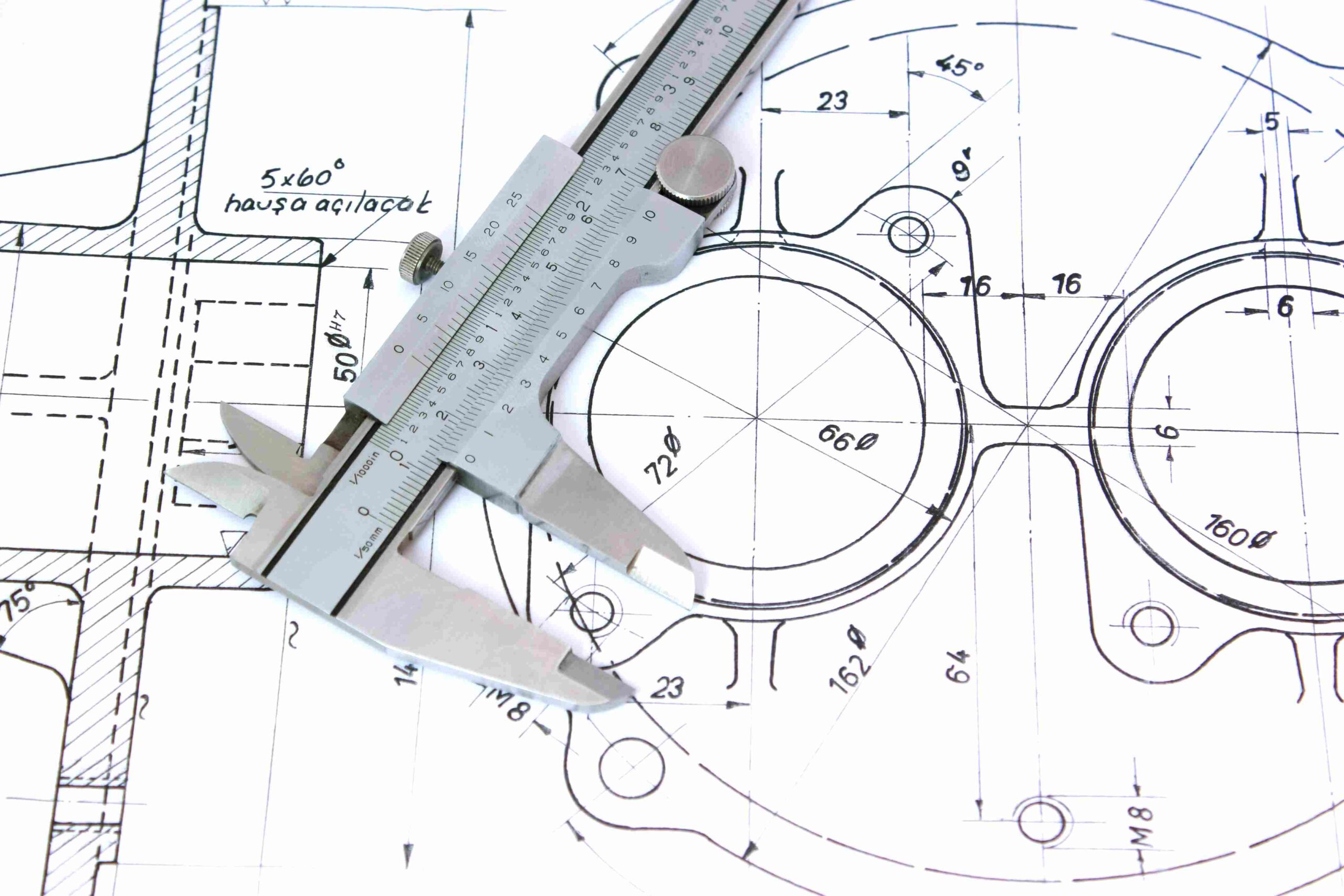

Please send your inquiries to the above email and provide as much detailed information as possible in your inquiry, e.g. 3D CAD models, 2D engineering drawings(which should detail materials, tolerances, surface finishing requirements, etc.), artwork files, and quantities needed.